Wall Panel Line - Horizontal

Lightweight Wall Panel Production Line - Horizontal Mold Car

Our Lightweight wall panel production line (Horizontal mold car) is a new type of wall panel production line developed based on our special experiences and mature technology.

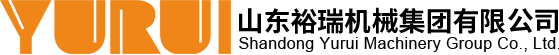

Compare with the vertical mold car, the horizontal mold car could produce three types of wall panels with different molds. Includes EPS Cement Sandwich Panel, Solid Wall Panel (without surface board) and hollow core wall panel. If you would like to produce the hollow core wall panel, the horizontal type is the best choice. If you want do produce sandwich panel, you also could check our vertical type.

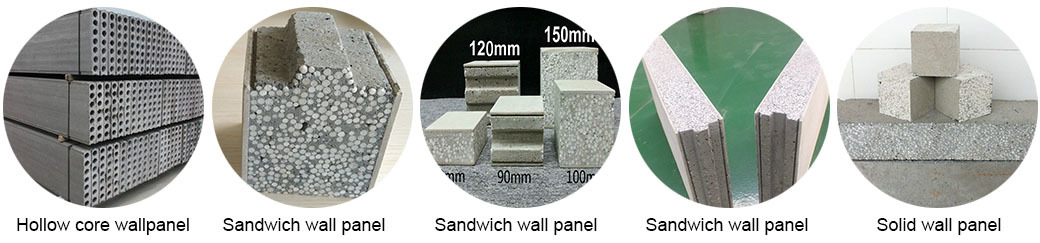

This type of production line mainly includes a automatic materials feeding system, automatic metering system, mixing system, casting system, horizontal mold cars, Mould car circulation system and demolding system.

This production line configuration is flexible, that means it could be adjust based on your requirements, such as the production capacity, automation, finished product specification. You could contact us for more suggestion and details, we will help you to find the best solution.

Finished Product Information

This production line could produce EPS Cement Sandwich Panel, Solid Wall Panel (without surface board) and hollow core wall panel.

The size of the board is adjustable and could be customized based on your requirements, below is the most popular range for your reference:

|

Specification |

75 series |

90 series |

100 series |

120 series |

150 series |

180 series |

200 series |

|

Thickness (mm) |

75 |

90 |

100 |

120 |

150 |

180 |

200 |

|

Length (mm) |

2400~3000 |

2400~3000 |

2400~3000 |

2400~3000 |

2400~3000 |

2400~3000 |

2400~3000 |

|

Width (mm) |

600 |

600 |

600 |

600 |

600 |

600 |

600 |

|

Density(kg/m³) |

55±5 |

60±5 |

60±5 |

72±5 |

88±5 |

88±5 |

88±5 |

|

Fire endurance(h) |

2h |

3h |

3h |

4h |

4h |

4h |

4h |

Technical Data for reference (based on 90mm thickness)

|

Test Item |

Unit |

Standard |

Test Result |

Judge |

|

Density |

Kg/m3 |

≤120 |

85 |

Pass |

|

Flexural Resistance Load |

/ |

≥1 |

2.6 |

Pass |

|

Compressive Strength |

MPa |

≥5 |

8 |

Pass |

|

Softening Coefficient |

/ |

≥0.8 |

0.82 |

Pass |

|

Drying Shrinkage |

Mm/m |

≤0.6 |

0.6 |

Pass |

|

Moisture Content |

% |

≤12 |

10 |

Pass |

The finished products could be widely used to different projects and buildings. Below are some pictures for your reference.

Production Process

Here we also have a introduction video of the production line for your reference: https://youtu.be/N3WQ4D5y9DA

Advantages

1.Lightweight: The lighter material of the wall panel is only weighs 25% to 40% of the weight of the traditional bricks. The amplitude reduces the longitudinal load of the building structure, reduces the building's own weight, and reduces the construction cost.

2.Installation faster: wall panel Install faster 4 Times than the regular blocks So save much labor cost.

3.Impermeability: The water absorption rate of lightweight composite wallboard is only 3.3%, which has reached the international advanced level in the same industry.

4.Fireproof performance & High thermal insulation: The fireproof capacity of the 90mm thick wall panel can reach more than 3 hours.

5.Sound insulation function: Because the lightweight composite wall board is made of polystyrene as the sandwich material, it has good sound insulation effect, and the hollow sound insulation is more than 40 decibels, reaching the national industry standard.

6. Save installation cost: Wall panel does not need the expenses of the work of the plaster on the surface.

PROVIDE SOLUTIONS FOR YOUR INDUSTRY