Building Materials Production Line

Mgnesium Oxide Board Production Line

The MgO board is a great fireproof building materials and panels used in different areas, it has excellent fireproof performance. This production line is energy efficient to produce the MgO board, which could reduce the waste and capture carbon dioxide during production. Besides that, the boards' fungus resistance means they attract no rot, mildew, allergens, or mold. It's 20 to 30 percent lighter than other cement-based boards. It becomes more and more popular.

View DetailsFiber Cement Board Production Line

Our machine line solution is a new type of production solution in the fiber cement board. It is a type of flow-roll forming process, with no need for high temperature and a high-pressure curing process. Traditional production lines use autoclave which needs a big area and energy, and the cost is also higher. Our production line doesn’t need it. The production speed is about 300pcs/hours based on 10mmx1220x2440mm.

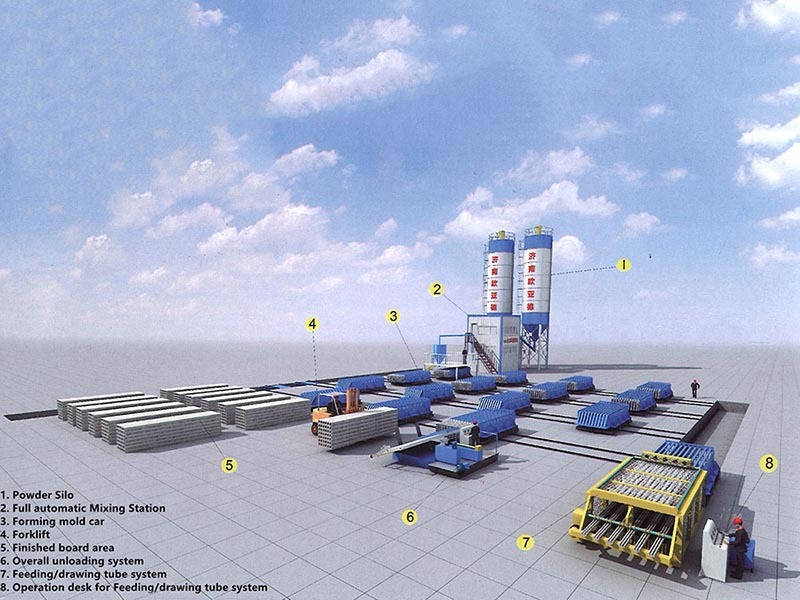

View DetailsOur Lightweight wall panel production line (Horizontal mold car) is a new type of wall panel production line developed based on our special experiences and mature technology. The horizontal mold cars is more flexible to produce different length of wall panel. The horizontal mold car can produce 20 pcs per set-We are the first Chinese factory to develop this kind machine to produce more panels per set car. In this way customers can save labor cost. Compare with the vertical mold car, the horizontal mold car could produce three types of wall panels with different molds. Includes EPS Cement Sandwich Panel, Solid Wall Panel (without surface board) and hollow core wall panel. If you would like to produce the hollow core wall panel, the horizontal type is the best choice.

View Details1.Double functional in producing sandwich wall panel and solid wall panel. Its surface plate used cold roll steel plate , so that can guarantee the wall panel are straight ,besides the plate is durable. For solid wall panel,Shandong Ouayde is the first company to make the research and development for it. 2.Full automatic in opening and closing the mold car, then can save more labor cost, increase production capacity. 3.Higher production capacity for one set vertical mold car: It can produce 40 sheets wall panel(90*610*2440).

View DetailsCase Display

Eps Corcrete wall panel machine

EPS wall panel machine

Eps lightweight sandwich cement panel production line in UAE