Gypsum Cornice Production Line

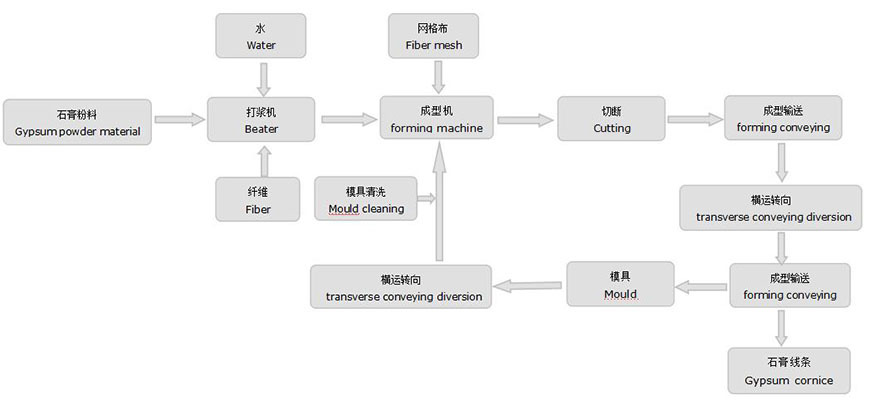

2、Mould is driven circularly through a full-frequency controlled transport system ;

3、Gypsum powder and water are delivered to the beater through special delivery equipment ;

4、Gypsum slurry is delivered into the mold, putting the fiber and fiber web into the slurry during the transmission process;

5、Gypsum slurry shape the gypsum cornice through the back line forming system, cutting into a single cornice after the slurry's initial setting, through acceleration, reversing then entering into the maintenance area, and maintenance when transmission;

6、Mold into the stripping zone, makes the plaster line out, and transported to the drying rack to dry.

Silo :

|

Daily capacity |

3000units |

6000units |

|

Equipment length |

60m |

100m |

|

Labor no. |

6 |

9 |

|

Installation power |

26.58KW |

28.5KW |

|

Equipment weight |

17T |

19T |

|

Operating speed |

12.5m/min |

25m/min |

|

Production efficiency |

900m/h |

1500m/h |

Remark: the manual gypsum cornice line with 3000units/day capacity will need about 30-35labors.

|

Raw materials |

Item |

Specification |

|

Constructional gypsum powder |

Fineness |

0.2mm,Remnant<10% |

|

Initial set time |

3.5-5.5 minutes |

|

|

Final set time |

7.5-10.5 minutes |

|

|

Crystal water |

4.5%-5% |

|

|

Semi-hydrated gypsum powder |

>65% |

|

|

Bending strength (2 hours) |

1.8 Mpa |

|

|

Forming water |

PH |

6.5-7.5 |

Fiberglass Meshes:

|

No. |

Capacity |

3000units/day |

6000units/day |

8000units/day |

|

2 |

forming |

2 |

2 |

2 |

|

3 |

demoulding |

2 |

3 |

4 |

|

4 |

transportation |

2 |

3 |

4 |

|

5 |

Total |

6 |

8 |

10 |

Advantage

mary

the

with

and

to

of

equipment

powder

alkali

glass

PROVIDE SOLUTIONS FOR YOUR INDUSTRY