Introduction of Phosphogypsum Gypsum Powder Production Line

Phosphogypsum gypsum powder Production Line is to processes chemical gypsum through drying, calcination, and grinding into gypsum powder that can be used in construction.

Our company masters the latest hot-air boiling furnace technology and hammer dryer technology for the production of chemical gypsum powder. The performance of the produced gypsum powder is better than other technologies, and it is more energy-saving and environmentally friendly, and can achieve high-capacity production

Paramater of Gypsum Powder Machine

|

Product Name

|

Phosphogypsum Powder Production Line |

|

Annual capacity

|

15,000 to 500,000 tons

|

|

Working time

|

24h/day ,300day/year

|

|

Raw Material Gypsum Type

|

Desulfurized gypsum from power plants |

|

Gypsum powder Mesh

|

Within 220 meshes

|

|

Heating method

|

Hot air boiling furnace

|

|

Application of the powder

|

Building material like to produce gypsum board ,

To make plaster of paris , to make gypsum cornice or ceiling

|

|

Degree of automation

|

Fully automatic

|

|

Fuel for the heating system

|

natural gas,coal,diesel,heavy oil,light oil etc

|

|

Packing method available

|

1. Packing machine 1-2 mouth

2. Rotary kiln packing machine

3. Iton bag packing machine |

|

Finished powder bending strength

|

2.7Mpa

|

|

Finished powder compressive strength

|

5Mpa

|

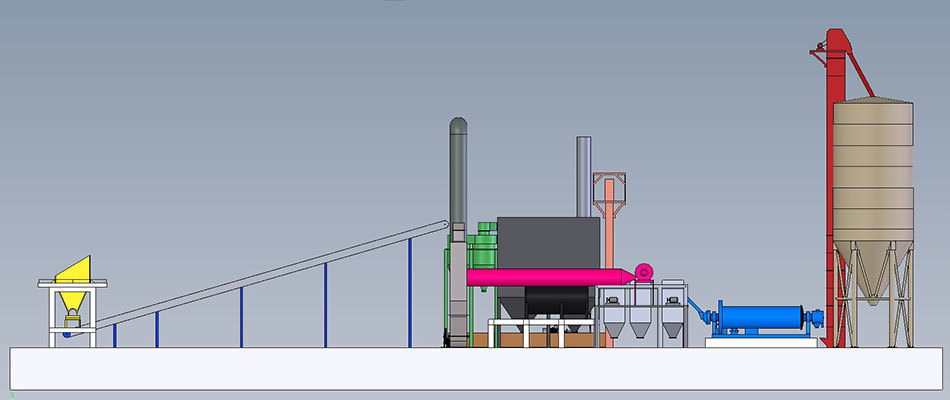

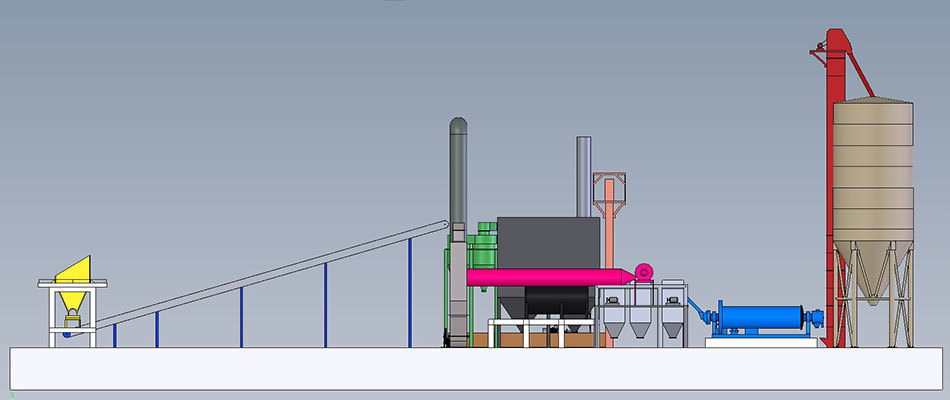

Main System of The Whole Production Line

First Step-Raw Material Conveying And Drying System

First Step-Raw Material Conveying And Drying SystemForklift put the raw material into the hopper, and then from the hopper to hammer dyer by the belt conveyor.

Second Step-Drying System

To dry the surface water of the powder with temperature around 500-700 degree,it can increase the liquidity of the gypsum powder and make it easy to calcine after come into the boiling furnace. it’s our core technology.

Third Step Cacinating System

The function of the boiling furnace is to remove crystal water and residual surface water. In this part ,we equipped waste heat utilization device, with this device , the waste heat can be reused in the hammer dryer to dry the surface water ,So the discharge heat temperatuer is low than 100,so it is more enegry saving .

Four Step-Milling System

This part is ball mill, because the chemical powder has quality problem, through modification mill, it can change the characteristic of chemical gypsum powder, make it similar to natural gypsum,it can increase the specific surface area of the powder

Then Packing Machine And Silo

After milling, the gypsum powder will come into the silo by elevator. For this part, if you want to produce plaster of paris, there will be some connection parts to plaster plant.

PLC Control System And Lab Equipment

Technology Advantage

1. Continuous output: using hammer dryer and soft start,

2. Stable quality: The modified mill can increase the specific surface area of the material.

3. Energy saving and stability: adopt the latest hot air boiling furnace technology, heat recycling, more energy saving

4. High performance equipment: use cloth bag dust removal, water bath desulfurization and denitrification treatment, and Greet brand inverter. , Siemens Electric, PLC, Guomao reducer, GB cable, electrical control: ABB.

5. Simple control: It adopts computer display and PLC control.

6. Mature experience: The core feature of our company is the mature technology for sale, which can lay a solid foundation for your company.

7. The maximum technical capacity can reach 1000 tons/day

8. Reasonable layout and low maintenance rate

9. Short installation and debugging time