Alpha Gypsum Plaster

What is Alpha Gypsum?

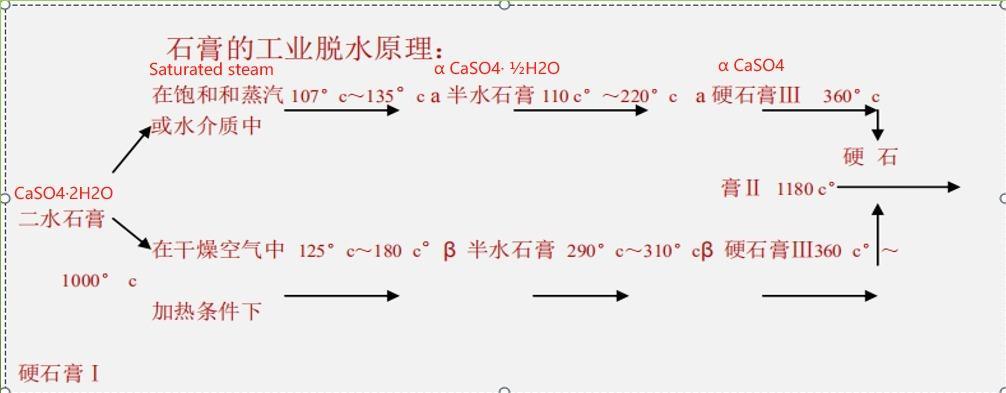

Gypsum is a versatile air-hardening cementitious material and is one of the oldest binding materials in use. Depending on the dehydration conditions of dihydrate gypsum, two different variants can be obtained, namely β-hemihydrate gypsum and α-hemihydrate gypsum. Both of these hemihydrate variants have the same chemical molecular formula, CaSO4 · ½ H2O, and their crystals belong to the trigonal crystal system; however, there are significant differences in the properties of their hardened forms. The term “high-strength gypsum” refers to a variant of α-hemihydrate gypsum obtained through thermal treatment of dihydrate calcium sulfate in the presence of saturated steam or certain salts and other solutions.

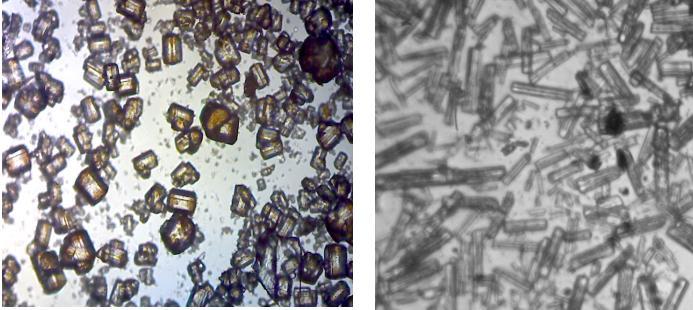

It is generally accepted that α-hemihydrate gypsum is high-strength gypsum. However, it should be noted that α-hemihydrate gypsum does not entirely qualify as high-strength gypsum; its classification depends on the crystallization morphology of the resultant hemihydrate gypsum. If the resulting hemihydrate gypsum consists of needle-like or fibrous crystals, the mixing water requirement will be greater than that for β-hemihydrate gypsum, and its mechanical strength will be significantly lower than that of β-hemihydrate gypsum. Often, variations in the production processes of α-hemihydrate gypsum lead to considerable differences in the final crystallization morphology, which in turn results in a wide range of mechanical strengths for α-hemihydrate gypsum products. For instance, the dry compressive strength of α-hemihydrate gypsum produced by autoclaving ranges from 25 to 50 MPa, while that produced through hydrothermal methods may differ greatly.

Alpha Gypsum vs. Beta Gypsum

Item | Alpha Gypsum | Beta Gypsum |

| Particle Shape | Dense, regular crystals | Loose, flaky particles |

| Manufacturing Process | High-temperature, high-pressure steaming | Atmospheric pressure drying and calcining |

| Strength | High (>30 MPa) | Low (<10 MPa) |

| Water Absorption | Low, fast demolding | High, prone to deformation |

| Application | High-end molds, decoration, industrial uses | General construction leveling, plastering, etc. |

Technical Specifications

Indicator | Unit | Parameter Value |

| Compressive Strength | MPa | ≥30 |

| Initial Setting Time | min | 8–12 |

| Final Setting Time | min | ≤25 |

| Fineness (passing 325 mesh) | % | ≥95 |

| Water-to-Mix Ratio | % | 60–70 |

| Dihydrate Gypsum Content | % | ≤5 |

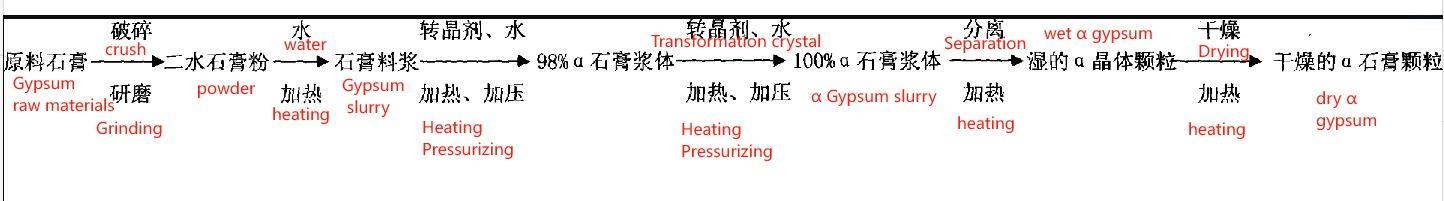

Production Flow Chart

Product Highlights

High strength: Compressive strength ≥30MPa, far higher than ordinary β-gypsum

Fast setting: Improves production efficiency, suitable for rapid demolding processes

Low shrinkage: Accurate finished product size, not easy to deform

High fineness: Uniform particles, smooth surface

High purity: Up to 95% or more CaSO₄·½H₂O

Application Fields

Building components: Gypsum board, ceiling, lines, background wall

Craft decoration: Sculpture, lamp molds, art models

Ceramic molds: Ceramic slip casting molds, high-precision reproduction

Medical models: Dental models, bone models

Refractory material base material: Enhanced density and strength

Quality & Certification

JC/T2038-2010 Alpha type high-strength gypsum Industry Standard

Grade | 2h Flexural Strength (MPa) | Dry Compressive Strength (MPa) |

α 25 | 3.5 | 25.0 |

α 30 | 4.0 | 30.0 |

α 40 | 5.0 | 40.0 |

α 50 | 6.0 | 50.0 |

Company Profile

Yurui (Shandong) Machinery Co., Ltd, is an enterprise integrating gypsum projects R&D, design, manufacturing, exportation, installation, and commissioning. We devote ourselves to helping customers quickly achieve projects establish and qualified finished products producing with our superior experience and strength in design, manufacturing, installation& commissioning.

We devote ourselves to helping customers save raw materials, and energy, and reduce the cost of production and equipment maintenance in long term with the most advanced gypsum equipment technology and the most mature gypsum production formula.

We have been deeply engaged in the field since 1994, setting up 100+gypsum projects domestic and abroad. Our engineers' group who only serve for YURUI left a full footprint over Africa, Asia, and South America, more than 20+countries. We hold different projects in each area, offering case visiting on-site. Besides we developed online visiting which breaks the limit of the virus.

PROVIDE SOLUTIONS FOR YOUR INDUSTRY