Introduction of Gypsum

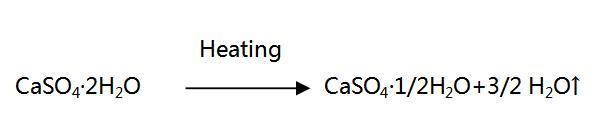

Natural gypsum generally includes dihydrate gypsum and anhydrous gypsum. In order to get the valuable materials, generally, we get semi-hydrated gypsum through heating the dihydrate gypsum. Here is the process:

The calcined semi-hydrated gypsum powder can widely be used for plasterboard,decoration board, gypsum block, stucco gypsum, and molding gypsum, etc.

Paramater of Gypsum Powder Machine

|

Product Name

|

Gypsum Powder Production line

|

|

Annual capacity

|

15,000 to 500,000 tons

|

|

Working time

|

24h/day ,300day/year

|

|

Raw Material Gypsum Type

|

Natural gypsum ore

|

|

Gypsum powder Mesh

|

Within 220 meshes

|

|

Heating method

|

Hot air boiling furnace or rotary kiln

|

|

Application of the powder

|

Building material like to produce gypsum board ,

To make plaster of paris , to make gypsum cornice or ceiling

|

|

Degree of automation

|

Fully automatic

|

|

Final product specification

|

Gypsum powder

|

|

Fuel for the heating system

|

natural gas,coal,diesel,heavy oil,light oil etc

|

|

Packing method available

|

1-Packing machine 1-2 mouth

2-Rotary kiln packing machine

3-Iton bag packing machine |

|

Finished powder bending strength

|

2.7Mpa

|

|

Finished powder compressive strength

|

5Mpa

|

Production Process

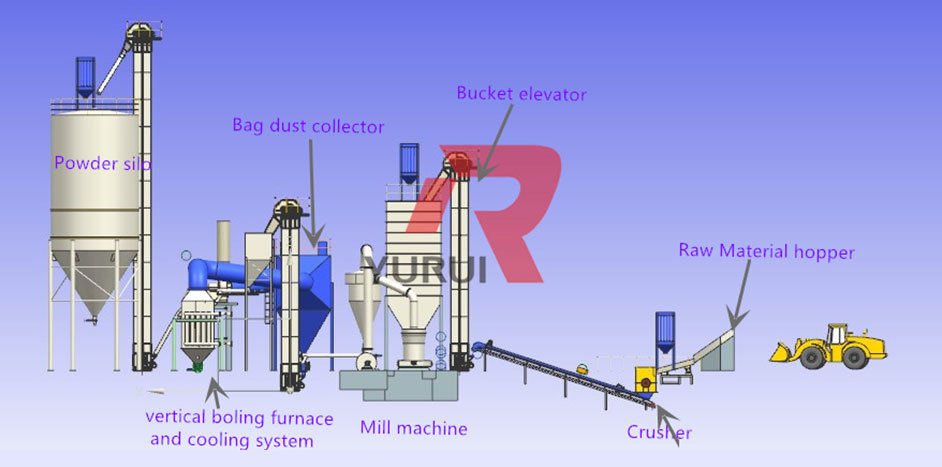

Crushing System

The crushing system can crush large ore from mine mining to an average granularity of 25 mm by one time, is an ideal version of traditional ways of two and three stage crushing.

Milling System

The mill system will make the gypsum particles into gypsum powder,through the combined action of analysis machine and fan, this mill can meet the fineness of grinding requirements from different users.

Calcinating System

Calcination system is the key link in the production and processing of gypsum powder, and it is also the most difficult part to master. According to this situation, we have developed a new generation of gypsum powder suitable for various application - a new type of hot air boiling furnace

Features Of This Hot Air Boiling Furnace Technology

1. Reduce investment

2. Reduce maintenance cost

3. Gypsum powder Quality adjustable

4. The installation period is short and the area is small

5. Energy and power saving

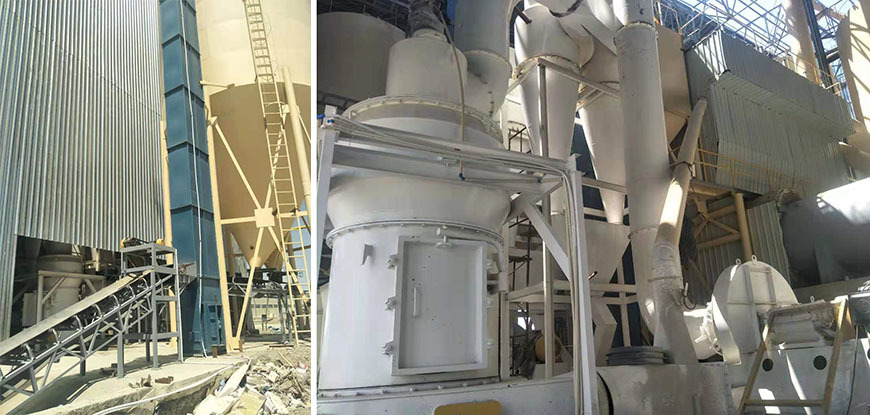

Storage and Packing system

Composed of the elevator, impeller feeder, finished product warehouse, packing machine and other equipment.

Technology Advantage

1. Continuous production: adopt soft starter,to make sure the continuous and stable production.

2. Stable quality: adopt latest hot air boiling furnace technology and cooling system , improve the quality of the product.

3. Energy-saving and stable: core technology cooling system and waste heat utilization system.

4. Equipment performance is high : adopt bag dust collector, frequency converter , Schneider Electric, PLC Mitsubishi and the national standard cable.

5. The control is sample : use computer display, PLC control.

6. Installation and commissioning period is short ,within 3-7 days.